Working hours:Mon - Sat 9.30 am - 06.00 pm Call us: +91-9974860012

Services

ESSENTIAL TOOL FOR PLANT RELIABILITY – PREDICTIVE MAINTENANCE AND CONDITION MONITORING TECHNOLOGY

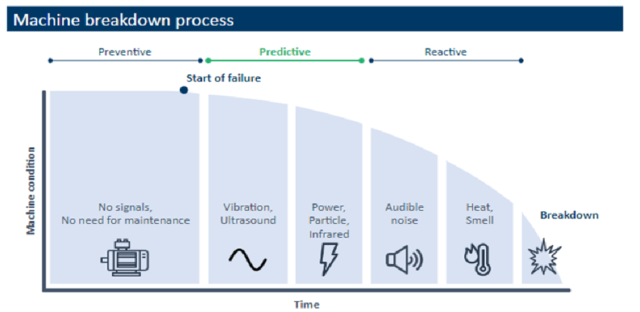

Predictive maintenance extends equipment lifespan, minimizes downtime, and maximizes profitability by catching issues early and aligning machine performance with manufacturer design.

For Management, the key question is how soon potential failures (Start of Failure) can be detected. Early detection allows for mitigating actions to extend the potential failure (Start of Failure) to functional failure (Breakdown) Interval, thus prolonging the machine’s remaining useful life. This forms the foundation of predictive maintenance.